REDWOOD LOGIN

Redwood PortalLTL

SCS

SCS Support

Rockfarm

The dreaded Last Mile, in Supply Chain Management terms, is the transportation of goods from a high-capacity port to their final destination (e.g. your home or office). Despite being just a fraction of the total distance traveled by freight, the last mile leg of the supply chain can eat up to 28% of the total cost of transportation (http://www.ipa.udel.edu/publications/FreightMovementCDBs.pdf). Carriers are working with new technology and increasing reliance on automation to reduce the costs of this critical final stage of delivery.

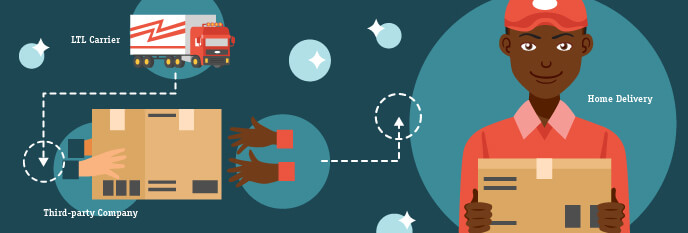

Traditionally, LTL carriers have stayed away from last mile delivery services, as the difference between bulk goods transportation and individual home delivery seemed too extreme to broach. But with continued revenue growth far from assured, more and more LTL carriers are entering the fray.

In today’s culture of convenience and instant gratification, consumers no longer feel the need to shop around or test out large items in the store, and are increasingly buying furniture and appliances online, sight unseen. Amazon, for instance, is making a huge push in the e-commerce furniture sector. LTL carriers have recognized that this trend can only increase, and are eager to capitalize. The barriers to entry are low, but to succeed and profit, LTL carriers must look to automating and upgrading tech in a business that hasn’t majorly changed for decades.

There are three major areas that LTL carriers can focus on to maximize efficiency and minimize costs of last mile delivery.

The first part of the Last Mile puzzle in which LTL shippers must automate concerns digital communication. Customers have grown accustomed to knowing not only when their delivery will arrive, but exactly where it is at every step of the process. Leading parcel carriers have all made strides in Track and Trace technology, but there has traditionally been less demand from LTL shippers for up to the minute tracking. In the field of last mile delivery, this feature is not a bonus, it’s essential. 3rd party logistics companies such as LTX offer freight management software that makes tracking and tracing shipments a breeze.

Ever heard of the Traveling Salesman Problem? “Given a list of cities and the distances between each pair of cities, what is the shortest possible route that visits each city and returns to the origin city”. This seemingly simple question has given rise to incredibly complex algorithms and yet still no general method of solution is known. All this to say that advanced Route Optimization software is absolutely key to tackling last-mile deliveries in a cost and time efficient manner. But automated software isn’t the final step here; UPS has thought creatively about this problem and taken it a step further. Upon realizing how much time and gas-mileage drivers were wasting at left turn intersections, the decision was made to eliminate all left-hand turns from routes. This unusual decision reduced their C02 emissions by 20,000 tons in one year.

LTL carriers new to the Last Mile delivery game have to decide whether to utilize their existing trucks for delivery or cross-dock to small delivery trucks (cross-docking means moving freight between trucks at the dock without ever entering the warehouse). LTL trucks serving a dual function as freight carriers and deliverers will need upgraded technology to help a single driver unload large goods. At the very least, trucks will need electrically operated lift gates to raise and lower freight to ground level – a feature generally not necessary for trucks unloading at a dock.

There are a lot of technological developments in the works that could completely alter the nature of the last mile over the next decade. Chief among those are Delivery Drones, Self Driving Trucks, and Unmanned Ground Vehicles. All are in the beta testing stage, and pending input from various regulatory agencies.

Delivery drones are already being used in some cities for small (under 5lbs) packages. In the U.S., drone delivery is still pending approval from the FAA – the number of obstacles in urban areas will make this a tricky industry to regulate, so expect strides to come in rural areas first. While this will influence only small parcel delivery for the foreseeable future, increases in drone carry-capacity means that drones will likely play a role in large item delivery decades down the line.

A more realistic solution for crowded urban area deliveries are Unmanned Ground Vehicles. Several start-ups, including Marble and Dispatch are exploring these autonomous delivery systems, most likened to refrigerators on wheels. These

Self Driving Trucks are already being tested in long-haul shipping, to the understandable consternation of truckers everywhere. The use of these in last mile delivery is likely much further out, due to the sheer amount of variability necessary in-home delivery. The rise of “white-glove service”, in which the carrier not only delivers large goods but installs/assembles them too, gives human operators a bit more job security too. The likely compromise between in-person and autonomous delivery could be some sort of hybrid – a driver operate a home-base truck in a certain area from which drones and ground vehicles deploy and return.

In the cut-throat shipping industry, carriers should welcome Last Mile delivery for the potential boost in profits. Last Mile Automation can help them face the significant expenses and inefficiencies of the sector.