REDWOOD LOGIN

Redwood PortalLTL

SCS

SCS Support

Rockfarm

In order to ship anything in the United States and Canada, a shipper must first understand cubic and linear footage and, more importantly, how to calculate it. Carriers across the continent utilize cubic and linear feet to determine the freight class of the shipment, calculate their rates, and allocate capacity to service the freight.

In order to understand cubic and linear feet, however, one must first know the difference between the two. Speaking logistically, a linear foot is 12 inches and is the unit of measurement used to account for the amount of space the freight occupies in one dimension, length. Cubic feet, on the other hand, accounts for the amount of space the freight takes up over three dimensions: length, height, and width.

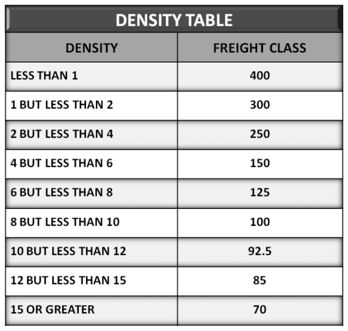

Cubic and linear footage measurements are utilized extensively by LTL carriers in order to determine the density of the total shipment. The density of the shipment is required in order to determine the National Motor Freight Classification as defined by the National Motor Freight Association. Cubic and linear footage requirements will ultimately determine how, when and at what rate the freight is shipped. Specific requirements can vary between carriers, but the industry standard for LTL (less-than-truckload) shipping is 12 linear feet and 750 cubic feet. Any freight larger than 12 linear feet, and 750 cubic feet is too large to ship via LTL and will require a FTL (full-truckload) carrier with a 48’-53’ trailer in order to accommodate. Calculating the cubic feet and density of a shipment can be done through a simple equation.

Cubic and linear footage measurements are utilized extensively by LTL carriers in order to determine the density of the total shipment. The density of the shipment is required in order to determine the National Motor Freight Classification as defined by the National Motor Freight Association. Cubic and linear footage requirements will ultimately determine how, when and at what rate the freight is shipped. Specific requirements can vary between carriers, but the industry standard for LTL (less-than-truckload) shipping is 12 linear feet and 750 cubic feet. Any freight larger than 12 linear feet, and 750 cubic feet is too large to ship via LTL and will require a FTL (full-truckload) carrier with a 48’-53’ trailer in order to accommodate. Calculating the cubic feet and density of a shipment can be done through a simple equation.

The linear foot rule is a transportation industry standard which states that shipments occupying 10 linear feet or more of trailer space are charged for 1000 lbs per linear foot. Understanding the linear foot rule is critical to a shippers LTL freight operations. Surpassing a carrier’s linear foot rule can result in extensive accessorial fees, high rates and a possible reclassification of the freight as a full truckload.

Most carrier contracts state that the carrier is in no way responsible for how the freight is loaded on the trailer and that the customer is responsible for any “over cube” charges. These costly mistakes can be avoided simply by predetermining the most effective way to minimize the linear footage that a shipment will occupy.

In order to abide by the linear foot rule, shippers should consider loading techniques like pinwheeling (turning a pallet 90 degrees so two pallets can fit next to one another in the truck), and double stacking pallets. These loading techniques minimize the amount of trailer space a load will occupy and allow shippers to utilize the generally cheaper less-than-truckload mode of ship, rather than a full truckload.

Many carriers have established rates when it comes to the number of cubic feet a shipment occupies, and for good reason. Light, low-density freight items can occupy far too much space in a trailer when compared to other heavier freight items. Products like packaged bubble wrap, cotton, and foam products do not have significant weight and will, therefore, have a lower density than other items of the same proportions. According to LTL carriers, in order for this freight to be priced fairly, it is rated according to cubic footage, rather than linear footage. Cubic feet requirements have been known to vary from carrier to carrier, however, most automatically adjust the weight of the shipment to no less than 6 pounds per cubic foot. An NMFC commodity class of 125 or 150 will then be applied to the shipment, along with the associated rates.

A common mistake among shippers is to measure their product and multiply that products dimensions by the number of product units that will be included in the shipment. This is a costly misconception as it does not take into account the dimensions and added weight of the shipping pallet and protective packaging. It is critical that shippers measure each shipment individually and with as much accuracy as possible in order to avoid the costly accessorial charges and fees that are associated with getting it wrong.

Knowing the exact dimensions of the freight is only half the battle, however, as communicating those dimensions accurately and correctly to the carrier, and the loading team, are just as critical to a successful shipment. Vehicle sizing, as the practice is called, establishes a specific, space and cost-effective loading pattern which loading teams can utilize to load freight according to linear and cubic footage rules and carrier specifications. This practice will only work if the shipper is aware of what type and size trailer the carrier will be bringing in to carry the freight.